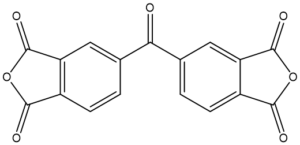

CAS Number: 2421-28-5

Synonyms:

- 4,4’-Carbonylbis(phthalic anhydride)

- 4,4’-Carbonyldiphthalic acid anhydride

- 3,3’4,4’-Benzophenonetetracarboxylic dianhydride

Starting in the late 1960s, BTDA found use in polyimide resins. BTDA-based polyimide films for electrical insulation, especially as substrates for flexible copper-clad laminates, are a crucial component of smart devices, including phones, tablet computers and Internet-of-Things componentry, as well as the growing network of 5G infrastructure.

Other polyimide applications utilizing BTDA include fibers for hot-gas filtration, foams for the thermal and acoustic insulation of military vessels, wire enamels and varnishes for electric motor assemblies, molding powders for industrial parts, and matrix resins for fiber-reinforced composites.

BTDA is available in a variety of particle types and purity levels. High-end polyimide and epoxy formulations use ultrapure grades of 99.8%+, while other applications use general-purpose 97-99% purity grades.

BTDA is a solid with a melting point range of 223-228°C. It was originally developed by Gulf Chemical in the 1960s as a curing agent for epoxy resins. BTDA has a lower melting point, movement within the molecule, and lower reactivity than more common dianhydrides. Epoxies cured with BTDA are typically rigid and have high glass transition temperatures, but exhibit less brittleness compared to other popular dianhydrides, making them ideally suited for powder coatings and molding powders in industrial as well as electrical applications.

RELEVANT ARTICLES

The Buy American Act: How May Your Business Be Affected?

An industry brief by Dr. Vinay Mishra, Technical Sales Manager [...]

What is Pultrusion?

Polymer composites offer high strength-to-weight ratios and other benefits such [...]

Entry 6 – High-Temperature Epoxy Adhesives Using Dianhydrides

Welcome to the sixth entry of The Dianhydrides Diaries, [...]