Pultrusion

Pultrusion is a unique process for fabricating glass- or carbon-fiber composites. Pultrusion creates a product with a functional shape and structural strength. Dianhydrides offer a way to manufacture a product with better strength retention in high-heat service. For improved processing, including higher pull speeds, dianhydrides can be matched with accelerators.

Adding BTDA as a co-curative to an anhydride is an effective way to boost thermal stability of pultruded parts. To improve thermal stability beyond levels achieved with monoanhydrides, dicyandiamide and phenolic curatives, neat BTDA is the preferred choice.

Mass casting

Curing molding resins or highly-filled matrixes with BTDA is an excellent solution for encapsulants, potting compounds, syntactic foams and electrical insulators. Any mass-cast part that requires maximum thermal stability can benefit from BTDA, especially without resorting to multifunctional epoxy resins. BTDA offers a very broad cure window (hours to minutes), a gentle exotherm for large parts, and can be blended with monoanhydrides if a pourable paste is desired for improved metering and mixing.

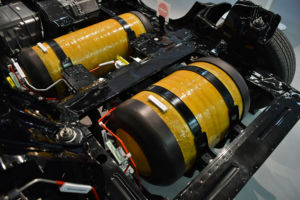

Filament Winding

This fabrication process produces cylindrical shapes, e.g., pipes, pressure vessels etc. Continuous fibers such as glass and carbon fibers are pulled through a wet and curable resin mixture and then wound on a mandrel or an inner liner to a desired thickness. This assembly is then thermally cured. For pipes, the mandrel is pulled out after cure. For pressure vessels, the inner liner becomes part of the final product. A variety of resin chemistries can be used based on the desired end application. BTDA-based epoxy formulations allow resistance to high temperatures, as well as most aggressive chemicals. BTDA will typically be dispersed in a liquid epoxy resin, making a slurry. It works well in combination with liquid anhydrides, such as MTHPA and NMA, which can help control the system viscosity for easier processing.

Prepreg

This a two-stage technique for producing composites. In the first stage, a glass or carbon fiber fabric is impregnated with resin and partially cured (advanced) to a minimally tacky state. This prepreg (pre-impregnated fabric) is sold in rolls to fabricators. Prepregs generally require refrigeration to prevent further cure from occurring. In the second stage, the fabricator lays up prepreg sheets in molds to build appropriate part thickness and then applies heat to induce the final cure. Some pressure is usually employed. This technique allows for minimal material handling and the avoidance of formulation errors.

BTDA-based epoxy prepregs resist high temperatures and chemicals during final service, as well as enhanced stability of the prepreg, often without refrigeration. Combining BTDA with liquid anhydrides such as MTHPA and NMA further allows optimization of the processing properties for the prepregger. Catalyst selection enables a range of cure profiles in the fabrication stage.

Dianhydrides such as BTDA and 6-FDA are also used to produce polyimide prepregs for aerospace composite applications.

Additive manufacturing

In contrast to traditional additive manufacturing processes utilizing thermoplastics, reactive additive manufacturing (RAM) leverages the best of epoxy resin/curative systems to fabricate prototype and large-scale composite parts, free of conventional forms and molds. Fillers include treated clays and silicas. Parts are “printed” and then subjected to post-curing for optimal property development.

RELEVANT ARTICLES

The Buy American Act: How May Your Business Be Affected?

An industry brief by Dr. Vinay Mishra, Technical Sales Manager [...]

What is Pultrusion?

Polymer composites offer high strength-to-weight ratios and other benefits such [...]

Entry 6 – High-Temperature Epoxy Adhesives Using Dianhydrides

Welcome to the sixth entry of The Dianhydrides Diaries, [...]