An epoxy resin is a thermosetting prepolymer consisting of epoxide and other functional groups. Epoxy resins can be cross-linked or homopolymerized into a three-dimensional network by utilizing curatives.

A wide range of curatives are offered for thermal or ambient curing. Examples include amines, polyfunctional acids, thiols, phenols, anhydrides and alcohols. They are frequently called curing hardeners or agents.

Types of epoxy resin include cycloaliphatics with saturated ring structures, those based on the Diglycidyl ether of Bisphenol A (DGEBA), tetrafunctional epoxies like Tetraglycidyl-4,4′-diaminodiphenyl methane (TGDDM), and epoxy novolaks based on formaldehyde and phenol.

Various grades of epoxy resin can be combined to attain the target properties or to decrease total costs.

Continue reading here

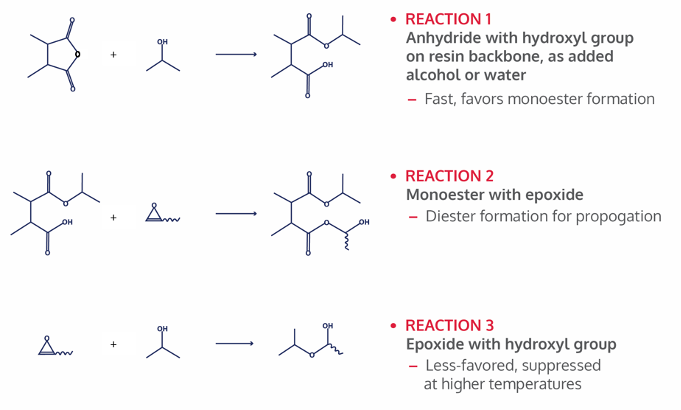

The three prominent reactions are involved in the curing of epoxy-anhydride formulations:

In Reaction 1, an anhydride group is opened to create a half-ester and a free carboxylic acid. Typically, this is triggered by a hydroxyl group, as shown, which may come from an accelerator, or the pendant hydroxyl on the epoxy resin. In Reaction 2, the newly generated carboxylic acid group reacts with an epoxide, creating an ester linkage and generating a new hydroxyl group, which subsequently reacts with another anhydride group as shown in Reaction 1, and so on.

Reaction 3, etherification, leads to homopolymerization of epoxy resin. This undesirable reaction reduces the crosslink density of the final network. To prevent residual anhydrides left over in the system, most commercial formulations use an excess of epoxide over the anhydride. The optimal anhydride/epoxide equivalent ratio (A/E) can be anywhere from 0.5 to 1.0 and is determined empirically to maximize the desired performance properties.

RELEVANT ARTICLES

The Buy American Act: How May Your Business Be Affected?

An industry brief by Dr. Vinay Mishra, Technical Sales Manager [...]

What is Pultrusion?

Polymer composites offer high strength-to-weight ratios and other benefits such [...]

Entry 6 – High-Temperature Epoxy Adhesives Using Dianhydrides

Welcome to the sixth entry of The Dianhydrides Diaries, [...]