Many products fall under the umbrella of adhesives but there are crucial differences among them. High-temperature (HT) adhesives are extremely durable and complex. They’re the go-to adhesives for service environments over 100℃, while quick-drying glues that you find on store shelves only operate from ambient temperature (20-30℃) to around 50℃. These heat-withstanding properties make high-temperature adhesives an ideal solution for technology, transportation, energy, and aerospace applications. Capable of performing under temperatures as high as 300℃, polymer high-temperature adhesives are even used for satellites in space.

High-temperature adhesives are either one component (1K) or two (2K) components. 2K adhesives, especially those based on epoxy resins, are the more common variety and are frequently made using a dianhydride curing agent. The combination of an epoxy resin, a dianhydride, and heat makes cured adhesives extremely heat resistant. They also weigh significantly less than mechanical fasteners, like nuts and bolts, and spread the joining forces uniformly across substrates, making the joint design much more efficient.

Intrigued? Here are six more things that make high-temperature adhesives unique.

- You won’t find high-temperature adhesives at big box stores.

If you’re looking to buy a high-temperature adhesive, you need a business-to-business provider. While big box stores sell name-brand products, these fast-drying, ambient-cure adhesives are only designed for the consumer market, which places more value on ease-of-use. In demanding industrial settings, these products simply do not match the performance of their heat-resistant cousins.

In addition, because of their more sophisticated chemistry, high-temperature adhesives require greater finesse in handling than ambient-cure adhesives. High-temperature adhesives often need personnel specifically trained in preparing substrates and cleaning surfaces before and during application.

- But you will find high-temperature adhesives in a lot of familiar applications.

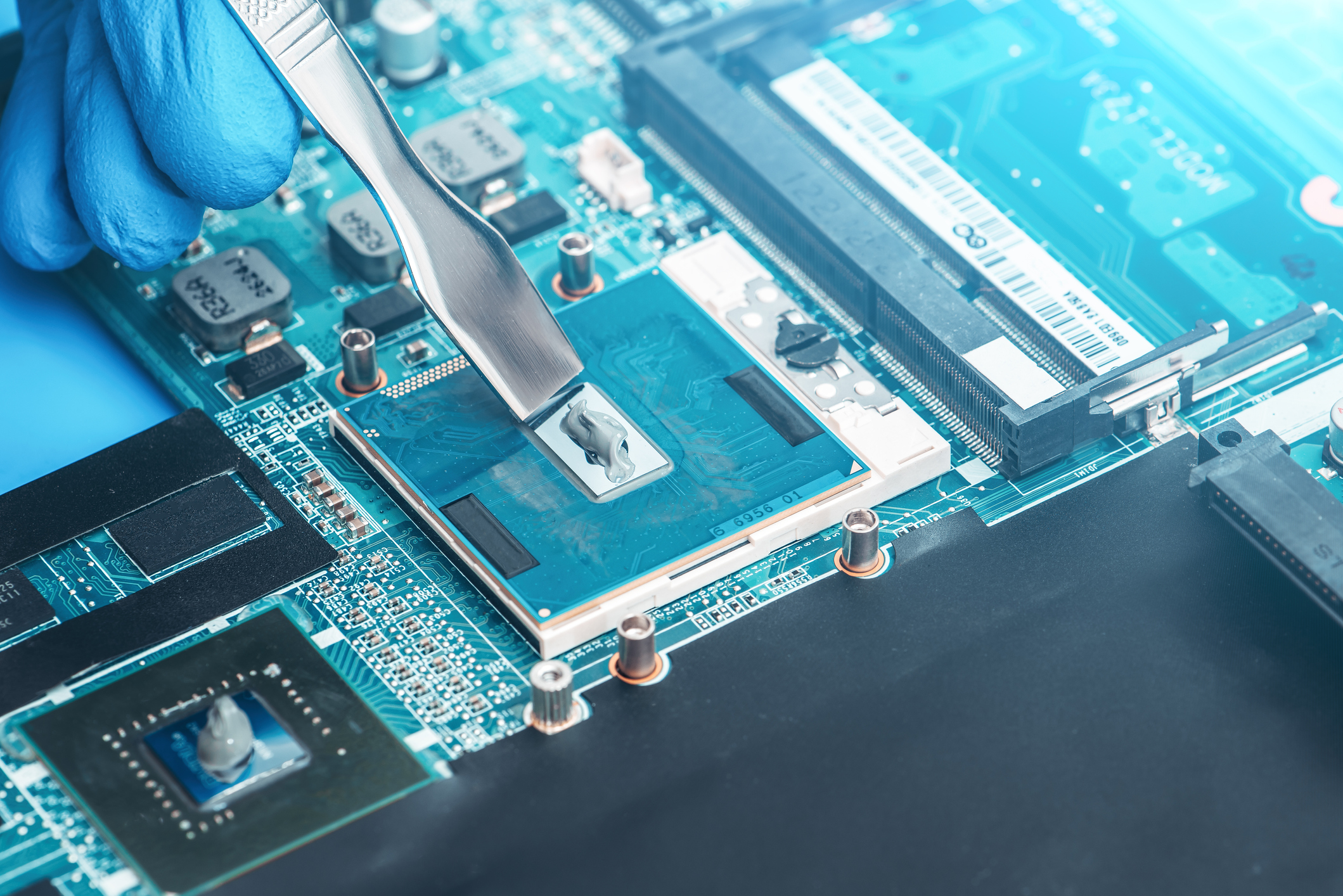

High-temperature adhesives may require more effort to design, but they are extraordinarily important to many industrial, manufacturing, and commercial applications. High-temperature adhesives are the glue in a vast range of electronic devices, including phones, watches, computers, and televisions—from semiconductors, circuit boards and sensors to the film adhesive behind glass screens. High-temperature adhesives are also integral to the full span of transportation vehicles: boats, motorcycles, cars, trucks, and now e-mobility.

As good as high-temperature adhesives are on the ground, they also excel in the sky. You can find high-temperature adhesives throughout the aerospace industry, including planes, rockets, missiles, satellites, and drones.

Through proper formulating, high-temperature adhesives can easily acquire additional features that range from one extreme to the other, such as thermal insulation or conductivity, and electrical insulation or conductivity. With their ability to withstand extreme temperatures and be either electrically conductive or insulative, these adhesives are crucial to batteries, motors, and various electrical components. In the energy sector, you’ll find them binding components of photovoltaic cells—a major part of solar panels.

- Ambient-cured adhesives are not designed for high temperatures.

Because their chemistry is only designed to cure at ambient temperatures, general-purpose adhesives are unable to reach high-temperature performance. As service temperature increases, ambient-cure adhesives dramatically lose their strength and fail to hold the adhesive joint. Meanwhile, high-temperature adhesives are designed differently. When cured with heat, they reach a high level of chemical crosslink density, which leads to their high-temperature performance (often denoted by their glass-transition temperature).

- High-temperature adhesives can be astonishingly durable.

Due to their high chemical crosslink density, high-temperature adhesives are the adhesive of choice for some of the most challenging conditions and applications. In addition to retaining their strength when exposed to service temperatures, they also resist chemical degradation from long-term exposure to environmental factors, including heat, oxygen, water or moisture in the air, and corrosive chemicals. Properly designed and cured high-temperature adhesives can withstand these aggressive environments because of their exceptional thermo-oxidative stability (TOS) as well as their resistance to hydrolysis or chemical attack. By customizing the specific formulation, designers of high-temperature adhesives can ensure they have sufficient durability, strength, and stiffness for the specific end-use.

- High-temperature adhesives are versatile.

With their ability to be either electrical insulators or conductors, high-temperature adhesives are remarkably versatile. In rigid printed circuit boards (PCBs), where high-temperature adhesives allow for sensitive and durable interconnections, they conduct electricity. On the other hand, in flexible, copper-clad laminates (FCCLs) for smartphones, where layers of electrical circuitry need to be kept separate, high-temperature adhesives can provide electrical insulation. In both cases, high-temperature adhesives can withstand exposure to electrical voltage.

The same applies for heat. In computers and smartphones, where it is crucial to limit the internal buildup of heat, thermally conductive adhesives help dissipate warmth to the device’s external surfaces or air. This allows for uninterrupted operation of these always-on devices and prolongs their lifespan. In opposite circumstances, where it is crucial to prevent heat from getting to a particular area of the adhesive assembly, a thermally insulative adhesive blocks the heat flow while bearing the brunt of the high heat itself.

- Ad-hoc remedies can’t be substituted for high-temperature adhesives

When properly engineered, 2K high-temperature adhesives are formulated with carefully selected, exactingly proportioned raw materials, e.g. an epoxy resin and a dianhydride curing agent. Each high-temperature adhesive’s success is also dependent upon a precise combination of curing temperature and time. Formulators who aren’t deeply versed in high-temperature adhesive chemistries can easily underestimate the care required to design such products. While a product may seem to perform well initially, without adequate stress testing, bonding durabilitycan’t be confirmed.

Unfortunately, it is not uncommon for formulators to add new ingredients into a known formulation, resulting in unnecessary complexities and a suboptimal solution. A better approach is starting from scratch and carefully selecting materials for the specific adhesive application.

The experts at CABB have an in-depth understanding of not only the science behind high-temperature adhesives but also the art of formulating them for the highest performance standards. We’ve helped companies across the globe bring their products to market—and perform with safety, consistency, and endurance.

Interested in learning more about high-temperature adhesives? Check out dianhydrides.com