Welcome to the fifth entry of The Dianhydrides Diaries, a bi-weekly series that will explore all the benefits of dianhydrides, along with the chemistry, applications, tips, and advice on how to gain a competitive edge with your next project.

The core of any electrical wire is typically copper metal, which carries current for the larger device. However, another important but understated component is the wire insulation, which prevents the circuits from getting shorted or other dangers. Common wire is insulated with a thick plastic material, frequently colored to identify hot/neutral/ground wires. The wire diameter can be twice or several times that of the core conductive wire, and it works well for most applications. However, when wire is coiled for electric motors, such thick insulation is impractical.

That is where an extremely thin but highly efficient insulating enamel saves the day. While several polymers can be used for this purpose, polyimide is the best choice. Its high electrical resistance allows using it in extremely thin layers as the primary insulation on bare wire. This in turn enables winding the wire into tight coils over itself (see Figure 1). The wire coated in this way is known as magnet wire, possibly because coils from such wire were used to create artificial, electro-magnets.

Figure 1. A motor’s rotor coiled with magnet wire coated with polyimide enamel, formed using a dianhydride.

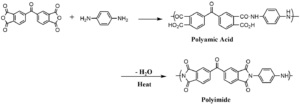

Polyimides are typically produced from the reaction of a dianhydride with a diamine in a two-step process (Figure 2). Step 1 produces poly(amic acid) (PAA) in an organic solvent. This solution is usually termed polyimide varnish, although poly(amic acid) varnish would be more correct.

In Step 2 (imidization), the bare wire is thinly coated with the varnish and heat is applied. The heat causes dehydration along the PAA backbone, releasing water and producing the polyimide. This step also flashes off the solvent, leaving behind a cured polyimide enamel on the wire.

Figure 2. Two-step process for producing polyimide varnish and enamel from a dianhydride and a diamine.

Polyimide varnishes and enamels offer superior dielectric performance over a wide temperature range from cryogenic to hot environments. In addition, their excellent thermo-oxidative stability and a near universal resistance to chemicals and moisture leads to uninterrupted performance throughout the lifecycle of the motor and at times even beyond.