Epoxy composites are a type of polymer material that uses an epoxy resin to create a polymer matrix which is reinforced with fibers or other fillers. This allows for the fabrication of long-lasting parts with very high strength-to-weight ratios. The low densities of epoxy composites compared to metals also offers substantial fuel savings in aerospace and automotive applications. Compared to traditional materials of construction—metal, concrete, wood, etc.—epoxy-based polymer composites are more resistant to deterioration from corrosion, spalling, or rotting.

Fibers such as glass, carbon, or even polymers ( e.g. aramids) provide much of the load bearing capability for polymer composite-based parts. The polymer (resin) acts as a binder (matrix) for the fibers, helping spread stress uniformly while providing an overall solid shape for the part. Different resin chemistries are available, each offering a unique set of benefits. This article highlights the epoxies used in composites; a broad resin class which offers several benefits over other composite matrix resins.

The benefits of epoxy composites

Epoxies allow for a low viscosity before cure, which assists in fiber wetting and saturation. This helps minimize air voids and maximize adhesion between the polymer matrix and the reinforcing fiber. Together, these factors help determine the strength of the overall epoxy composite. The low viscosity also enables the utilization of various composite fabrication processes, such as resin transfer molding (RTM, or infusion), filament winding, pultrusion, and prepreg techniques. Having various options offers the freedom to choose the best fabrication technique that is ideal for the specific part being manufactured. When cured, epoxies offer good chemical resistance, allowing the construction of composite pipes for use with chemicals and water. Epoxies can also be readily tailored to match the physical characteristics required in service. While they are generally thought of as strong and rigid materials, epoxy composites can easily be modified to enhance toughness against impact, and achieve flexibility where required.

Curing epoxy composites

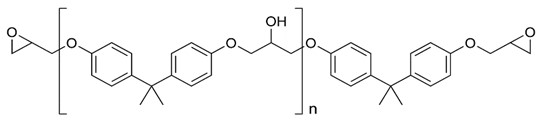

The term epoxy resin truly represents only one of two key parts of the polymer system. Figure 1 shows the structure of the most commonly used epoxy resins, based on the diglycidyl ether of bisphenol A. In addition, the term epoxy literally signifies only the terminal epoxide groups on such oligomeric resins. As such, a variety of chemical backbone structures are available as epoxy resins all containing epoxide functional groups.

Figure 1. The structure of the most frequently used epoxy resins is based on diglycidyl ether of bisphenol A.

The other critical part of an epoxy formulation is the curing agent. Curing agents come in even greater variety, as they can differ in their chemical backbone structures as well as their terminal reactive groups. Focusing the discussion below on the reactive groups alone, curing agents can be selected from polyfunctional amines, anhydrides, and catalytic curing agents such as dicyandiamides. Each curing agent class offers a unique set of benefits for end-product epoxy composites. Amines can allow curing at ambient temperatures, eliminating or reducing the need for ovens. Other curing agents, e.g., anhydrides, can offer higher temperature performance, when heated cure cycles can be used. Dianhydrides e.g., BTDA® (benzophenone tetracarboxylic dianhydride) are a subset of the anhydride-functional curing agents, and lead to the best high-temperature performance, even when working with the simplest epoxy resins.

During and after cure, most epoxy formulations offer zero VOCs and low cure-shrinkage which minimizes undesirable internal stresses in the fabricated part. This is a major advantage over unsaturated vinyl resins, which typically contain volatile styrene monomers, also requiring proper ventilation for minimizing fire hazard as well as respiratory hazard for workers. For specific requirements, epoxy cure shrinkage can be further minimized, e.g., when using anhydride and dianhydride curing agents. These curatives also lead to lower cure exotherms vs amines, helping eliminate hot spots in the part and related undesirable flaws.

In summary, the versatility of epoxy resin chemistry, with respect to easy fabrication of durable, light weight and strong structures, is clearly apparent. The resulting epoxy composites allow for newer ways of constructing higher performance and longer lasting components in many market segments including sporting goods, surface transportation, marine and aerospace, infrastructure and more.

BTDA is a registered trademark of Jayhawk Fine Chemicals Corporation